Standard features of Alpha Lazer cutting solutions

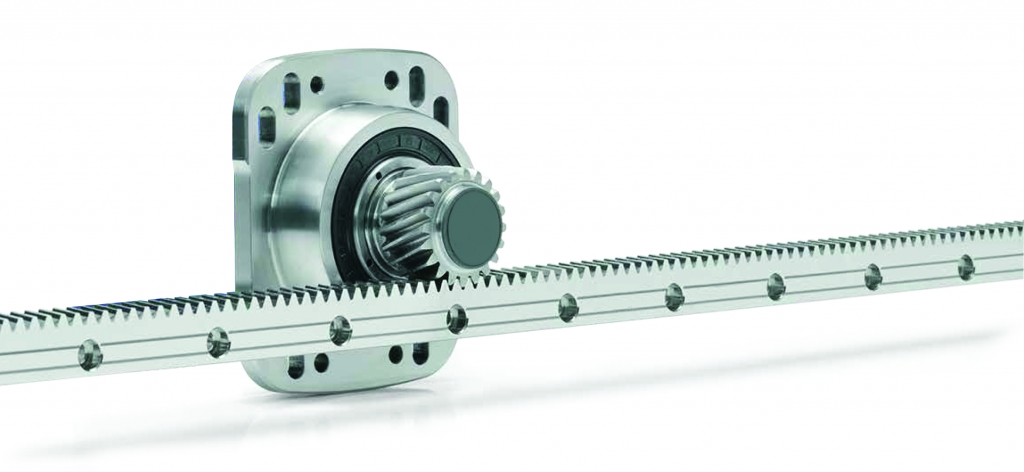

Direct Drive Rack & Pinion

Powered by high performance AC servo motors

The stable construction concept allows extremely high acceleration values.The axes are driven by dynamic low moment of inertia and high performance AC servo motors, that require no maintenance. There are no intermediate load transmitting elements between the motor and the pinion, which otherwise could cause loss of precision. High precision two-way, hardened helical racks with low running clearance make it possible to achieve very high acceleration and speeds.

Rigid Frame & Gantry

Rigid stress relieved welded steel frame construction

The foundation for all Alpha Lazer™ machines is a rigid stress relieved welded steel frame construction upon which a stiff gantry axis system moves the cutting head. The design guarantees accurate parts even when cutting with the fastest speeds and under the highest accelerations.

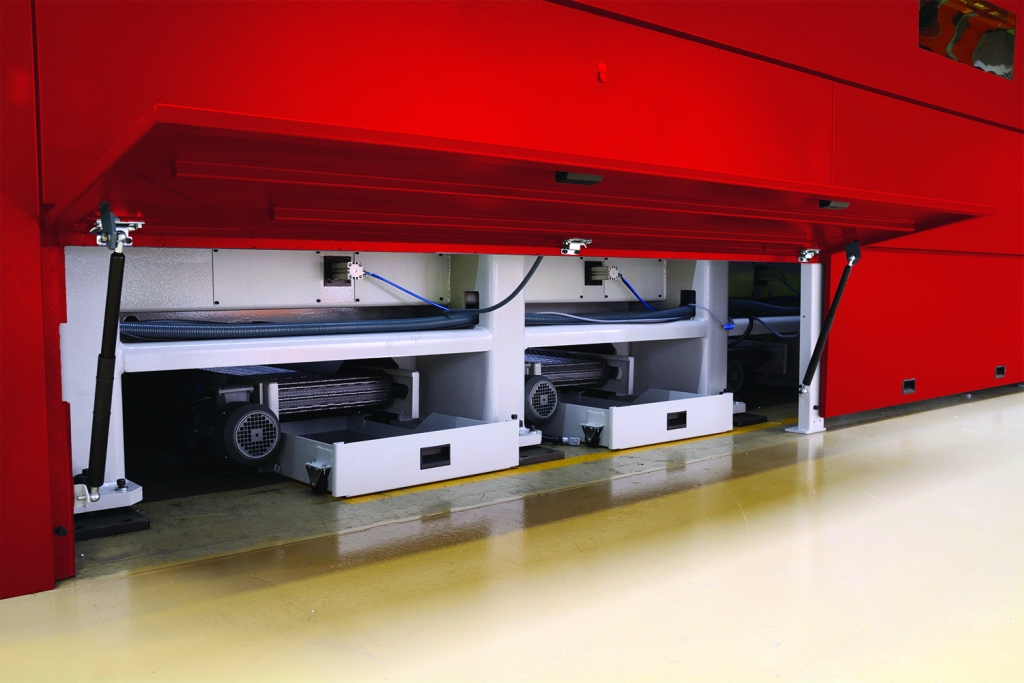

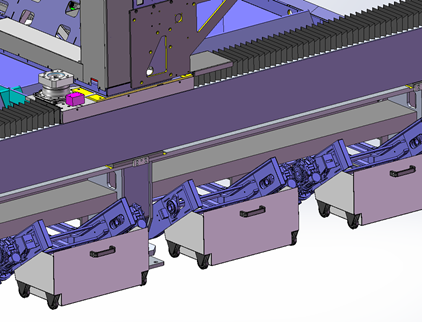

Shuttle Table

Integrated shuttle tables are incorporated on the laser machine to maximize productivity and minimize material handling times. The shuttle table and pallet change system allows convenient loading of new sheets or unloading of finished parts while the machine is cutting another sheet inside the working area. The tables are fully electric and maintenance free. There are no hydraulic oils to handle and the table changes take place fast, smooth and energy efficient.

Scrap Removal Drawers

Easy maintenance & trouble free operation

The standard lateral scrap drawers allow the removal of scrap pieces from the working area without the need to interrupt the cutting process. The sideways operation of the short conveyors allow for easy maintenance and trouble-free operation. Motorized conveyors are available as an option.

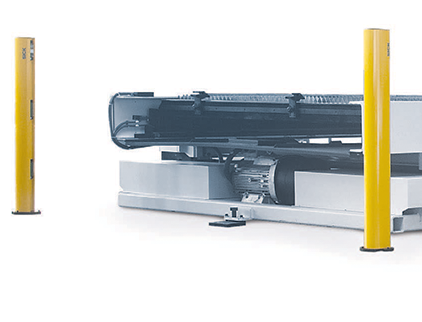

Safety & Protective Measures

The safety equipment corresponds to the current local guidelines

The laser cutting system, machine and CNC controller are equipped with safety devices. These switches and sensors protect the operator from hazards and counteract damage to the system. For example, incorrect path measurement programming or collision between the work piece and the machine. A diagnosis system keeps the operator informed about the current status of the system and allows him to intervene in the dialogue to make corrections that remedy these faults. The steps required for the solution appear as plain text on the controller screen.

The working area of the machine is guarded light guards. These guards can be interrupted to gain free access to insert a new sheet, lens and nozzle replacement, general maintenance and for other special purposes. During the laser cutting operation the safety devices are electromagnetically locked in order to prevent an accidental triggering of the machine’s EMERGENCY STOP function. The machine’s safety equipment corresponds to the local guidelines currently in force. The laser head is guarded along the Y axis by flexiglass material which allows clear vision of the cutting area.

Optional features of Alpha Lazer™ cutting solutions

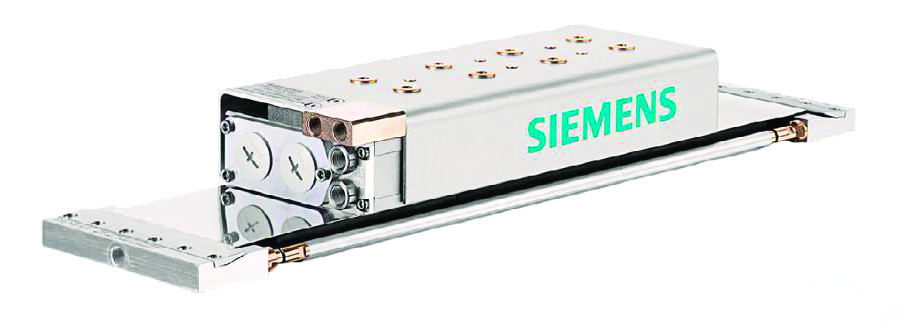

Linear Motion System

Offers higher dynamics than the rack & pinion system

State-of-the-art linear motors narrow down further the accuracy of the machine and offer higher dynamics than the rack and pinion system. When the application demands high precision and/or require many positioning movements between complex shaped features, the linear motors will reduce the dead times in the process and increase the productivity.

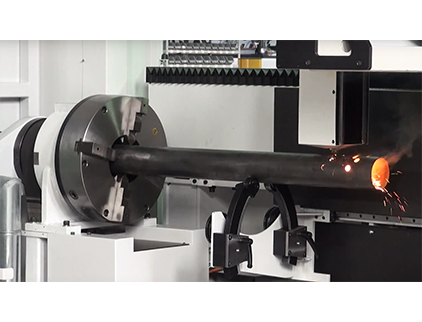

Pipe cutting attachment

Available on certain M-Series models

This attachment allows for pipe cutting on the same machine as sheet cutting.

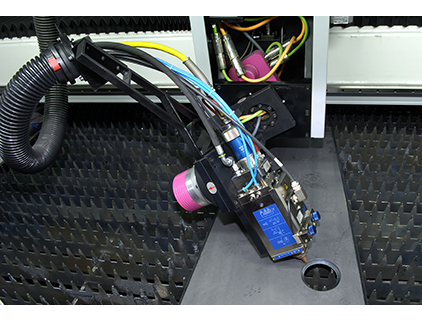

5-axis cutting head

The 5-axis cutting head allows for full contour beveling

The Alpha Lazer® 5-Axis Bevel head allows full contour beveling. Includes all software upgrades for Lantek expert so that it can generate 3D files to contour bevel toopath automatically. Maximum production Material tickness 10MM or 3/8″ amd maximum cutting area on 45 deg. bevel is 100″ wide.

Motorized Lateral Scrap Conveyors

Easy access & Easy maintenance

Three optional lateral scrap conveyors offer easy access, easy maintenance and low electrical consumption.

Compact Automation

Loading / Unloading unit with work queues of several sheets

Alpha Lazer’s automation compact footprint reduces floor space requirements, thereby lowering production costs. The CELL is a full-functional system expansion of the laser cutting machine: work queues of several sheets are activated by pressing one single button and there is no separate control panel for the loading/ unloading unit.

Model Description

Model Description