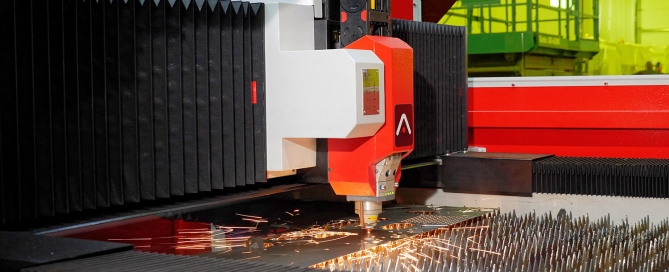

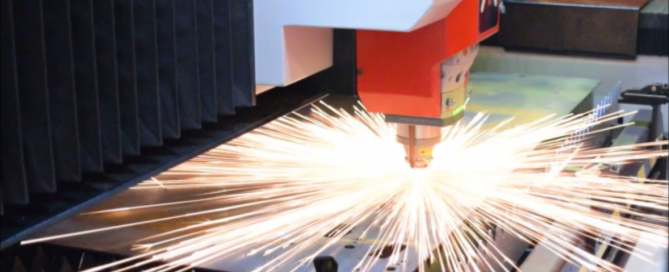

WHAT MATERIALS CAN A FIBER LASER CUT?

Fiber laser cutting is considered one of the most revolutionary technologies in the metalworking industry since CO2 lasers were introduced for cutting in the 1980s. Fiber laser systems feature a wide cutting range and fast cutting speeds and produce precise, high-quality edges. Consider that in just five years, fiber lasers have achieved the 4kW cutting [...]