Alpha Lazer uses high tech parts from world class suppliers

and pairs them with top class customer service and training

Precitec ProCutter laser cutting head

The PRECITEC ProCutter head offers a complete solution for the fiber laser cutting of thin and medium material thicknesses. Display of operating parameters via Bluetooth® (android phones) and interface for machine control, LED operating status display, drift-free fast-reacting distance measurement, motorized focus position adjustment for automatic machine setup and piercing work and lightweight and slim design created for fast acceleration and cutting speed.

*Available as an option for the Fiber SL model (except 0.5kW and 1kW)

Siemens SINUMERIK 840D SL Controller

Alpha Lazer machines achieve the highest dynamics and the fastest laser processing cycle times thanks to the combination of rigid mechanics and a state-of-the-art numerical control from SIEMENS. The graphical user interface ensures an easy operation of the machine and the on-board libraries of reference cutting parameters for various materials and thicknesses allow the operator to achieve optimal cutting results in a minimum amount of time. Programs can be loaded easily into the machine with a USB stick or over a fast Ethernet connection with the company network. The controller has a complete cutting database for all standard cutting applications and materials (steel, stainless steel, aluminium, etc.) for common thickness ranges.

Lantek Expert Cut CAD/CAM software

This technology reduces further the maintenance requirements and offers the lowest possible running cost with a wallplug efficiency of 30% and without the need of any laser gas. When the application requires a broader spectrum of material types to be cut and the maximum thickness range is limited, the fiber laser is the ideal solution. It will cut faster at lower cost than any CO2 laser at the same laser power.

*Hypertherm ProNest, SigmaNEST, Radan Radnest and other CAD/CAM software available as an option.

IPG Photonics YLS fiber laser sources

IPG Photonics Corporation is the world leader in high power fiber lasers and amplifiers. Fiber lazers have revolutionized the industry by delivering superior performance, reliability and usability at a lower total cost of ownership compared with conventional lasers, allowing end users to increase productivity and decrease operating costs. Excellent beam parameter product (BPP), small focus over large working distance, maintenance free operation, modular plug-and-play design, compact, rugged and easy to install, it has an estimated diode lifetime of up to 100,000 hours.

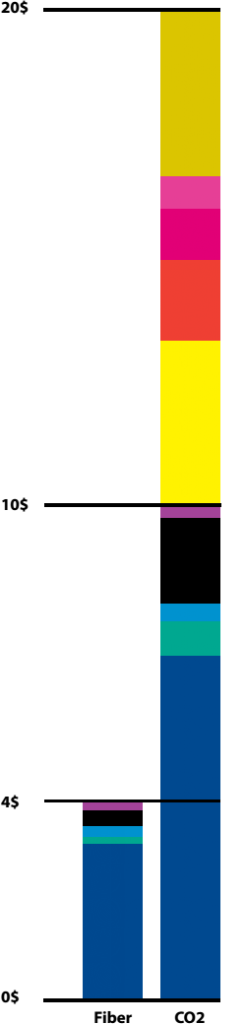

Advantages of Fiber lasers vs CO2 lasers

This technology reduces further the maintenance requirements and offers the lowest possible running cost with a wallplug efficiency of 30% and without the need of any laser gas. When the application requires a broader spectrum of material types to be cut and the maximum thickness range is limited, the fiber laser is the ideal solution. It will cut faster at lower cost than any CO2 laser at the same laser power.

• No need of gas to create laser beam

• Reflection of the laser beam is nearly zero to cut nonferrous metals such as copper and brass at low power with high efficiency

• Very low electrical consumption of 30% wall plug efficiency

• No need of mirror adjustment and nearly zero maintenance requirement

• Consistant Beam divergence

• Low operation cost

• Very low power consumption

• 4 times greater beam power density

• No CO2 gas turbine system

• No resonator refurbs

• No mirrors or alignment – ever

• Expected minimum diode life of 100, 000 hours

Sum of all utilization costs by laser technology

Model Description

Model Description